Butter Churner

21 x 36 x 14”

Powdercoated Steel and aluminum

2019

21 x 36 x 14”

Powdercoated Steel and aluminum

2019

The introduction of automation in industrial production can be traced to Ford Motor Company in the 1940s.From the moment machines could handle any sort of repetitive task, humans have worried about their own impending uselessness. Machines were designed which are intended almost totally to exclude the labor of the human race.

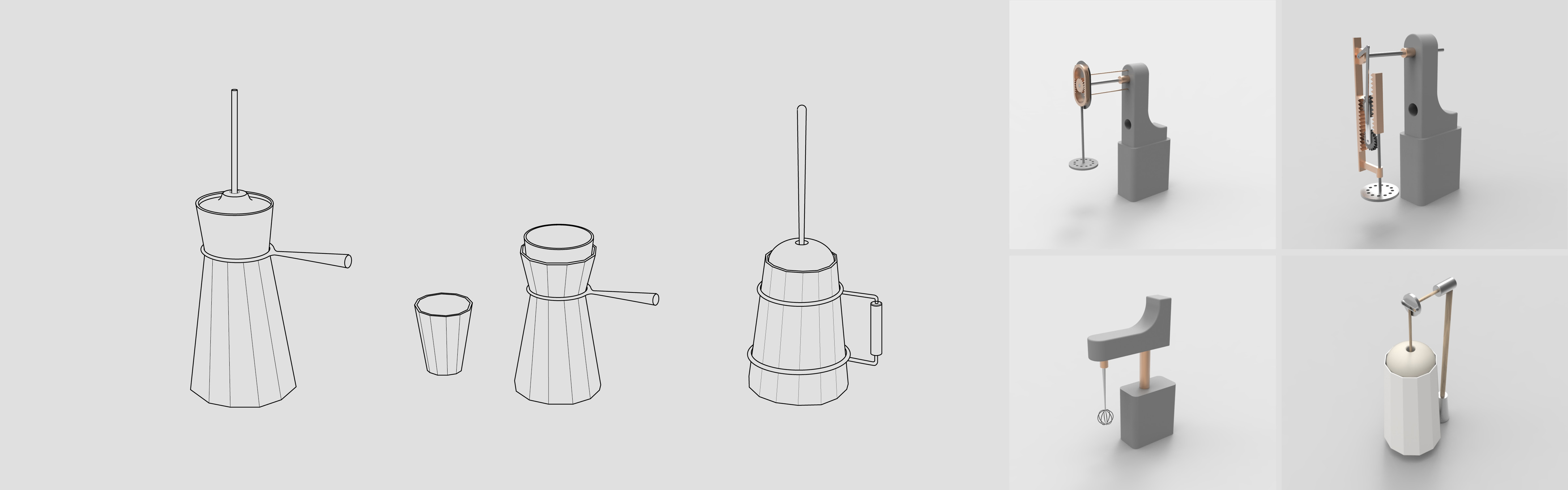

In our contemporary context there is an increasing cultural appreciation for goods and services that are directly connected to human providers including farmers, artisans, and brewers which begs the question: has automation made human labor more valuable? Formally inspired by the plunger-type butter churner used by 18th century American pioneers, “Butter Churner” is motor powered but operates at a human’s pace.

There is plenty to figure out with regard to how technology is reshaping our lives and economy without looking to the far distant future. The question isn’t whether more machines are coming; they are already here, and have been for a long time.

More information about this project: https://www.whatnotstudio.design/

In our contemporary context there is an increasing cultural appreciation for goods and services that are directly connected to human providers including farmers, artisans, and brewers which begs the question: has automation made human labor more valuable? Formally inspired by the plunger-type butter churner used by 18th century American pioneers, “Butter Churner” is motor powered but operates at a human’s pace.

There is plenty to figure out with regard to how technology is reshaping our lives and economy without looking to the far distant future. The question isn’t whether more machines are coming; they are already here, and have been for a long time.

More information about this project: https://www.whatnotstudio.design/

The Butter Churner is a one year long project which focused on the question: what is obsolescence? Native to human existence, our environments are in constant flux. The human/object relationship changes as new methods of making and modes of efficiency force new perspectives, and, subsequently, new objects. I chose the butter churner as my starting point is because it was replaced by churning machine, which also caused the obsolescence of the manually churning and mixing motion.

The introduction of automation in industrial production can be traced to Ford Motor Company in the 1940s. From the moment machines could handle any sort of repetitive task, humans have worried about their own impending uselessness. Machines were designed which are intended almost totally to exclude the labor of the human race.

The introduction of automation in industrial production can be traced to Ford Motor Company in the 1940s. From the moment machines could handle any sort of repetitive task, humans have worried about their own impending uselessness. Machines were designed which are intended almost totally to exclude the labor of the human race.

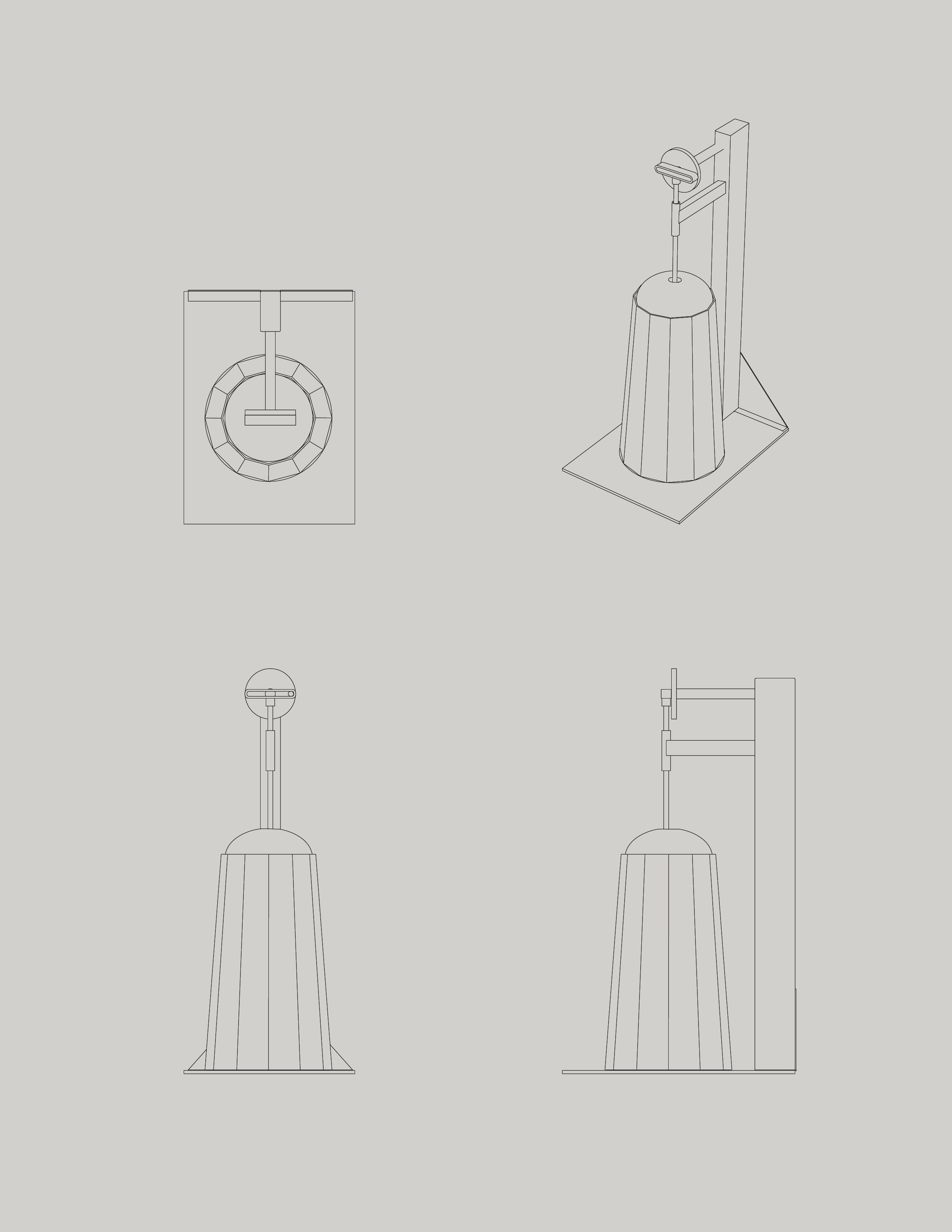

Form, function and mechanism thnking.

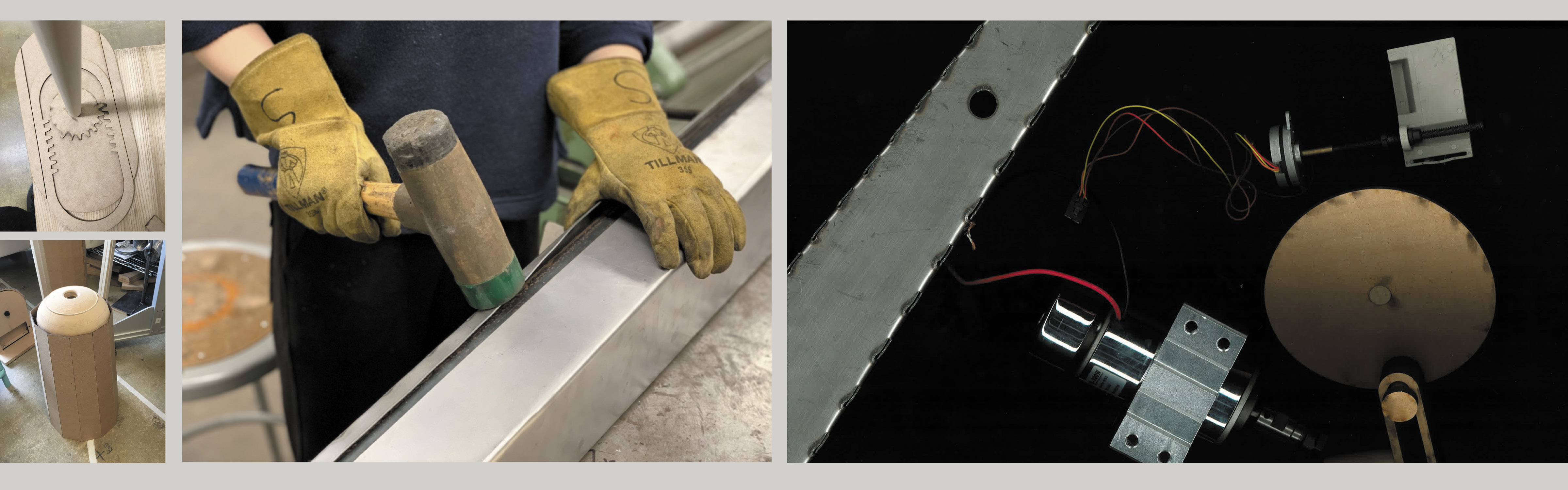

Prototypes

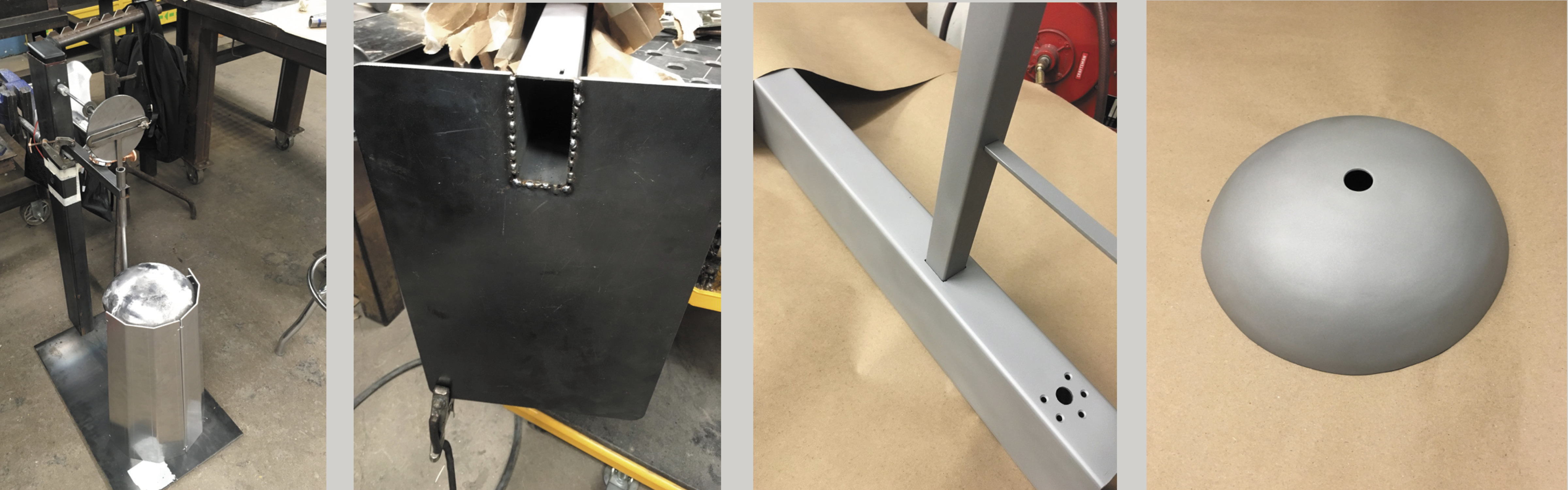

Instead of sending all the parts to a fabricator, I decided to make these mechanism structure by myself.

It was extremely challenging to transform a circular motion into linear motion. Without robot, everything needs to be calculated precisely by myself to make this piece run. The whole process collarboating with limited equipments made me think deeper about the relationship between machine and human labor and how valuable it is.